We are now offering you the possibility to use screen printing for your textile products. Therefore we would like to introduce this printing process to you in the following article. The screen printing process is particularly suitable for large print runs at attractive prices! Thanks to this screen printing process, we produce precise and extremely durable print quality. Our textile portfolio offers you many different products for which you can now choose the screen printing process.

Table of Contents

- The technology

- Production of the printing plate

- The printing process

- Screen printing

- Advantages and disadvantages of screen printing

- Our products

- Why choose screen printing?

1. The technology

The screen consists of a frame covered in fabric. The quality of the screen fabrics varies in the screen fineness and the thread or wire diameters. Since screen thickness and mesh size influence ink film thickness and ink application volume, the printing form is selected according to substrate or ink. If the substrate is particularly fine or the design is rich in details, screens with finer thread counts must be selected.

2. Production of the printing plate

The screen becomes the printing plate for the screen printing process as soon as the stencil is applied to the screen. The stencil prevents the application of ink to those areas of the printed image that are not to be printed. In order to produce the stencil, the screen fabric is coated on both sides with a light-sensitive copying layer. The motif to be printed is then exposed in an exposure unit with the aid of a light source with a high UV content. In this special copier, the screen is pressed onto a glass pane with a vacuum and exposed through the glass pane. The exposure ensures that the emulsion becomes waterproof, which means that only the areas covered by the film remain water-soluble. After the printing form has been washed out, all remaining and unexposed areas of the copying layer are then washed out so that the stencil can be used for printing.

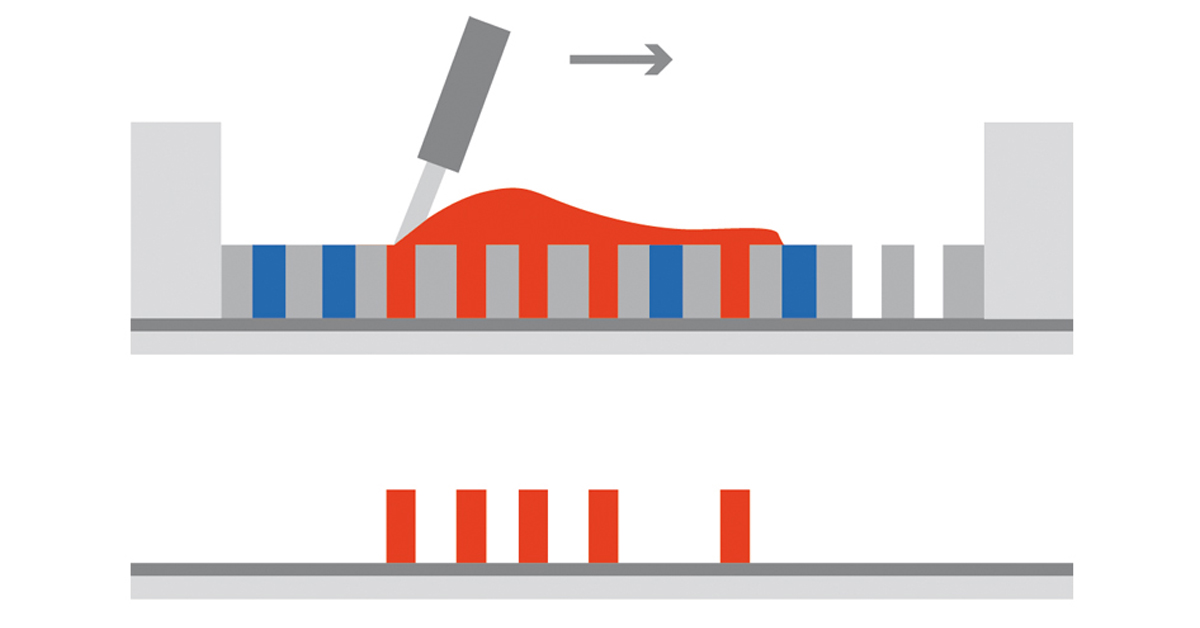

3. The printing process

4. Screen printing

5. Advantages and disadvantages of screen printing

| Advantages | Disadvantages |

|---|---|

| Large print runs at an attractive price | Only profitable with large print runs because of a lot of preparatory work |

| Vibrant/Intensive colours | Slower printing speed than other printing processes |

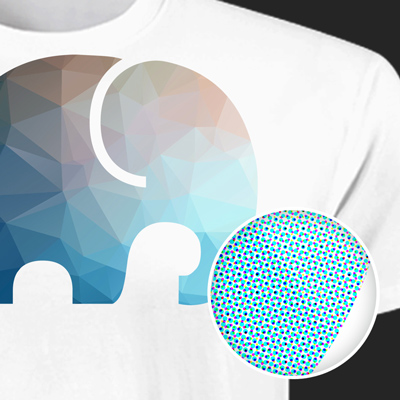

| Different surface structures (fine, coarse etc.) printable | No smooth colour gradients possible (halftone printing is possible) |

| High precision possible | |

| Ink application can be varied so that high ink film thicknesses can be achieved |

6. Our products

The following SOL’S products are now available with screen printing:

T-shirts

- for women, men and children

- many different colours

- numerous printing areas possible (e.g. front/back, neck, sleeves)

Polo shirts

- for women and men

- up to six different colours

- Print on the front and back or on the sleeves

Long sleeves

- for women and men

- three colours

- Print on the front/back or sleeves

Zip-up Hoodies

- for women and men

- four colour variations

- numerous printing areas possible (front side chest area, back side, sleeves)

Hoodies

- for women and men

- seven different colours to choose from

- Printable on the front and back, as well as sleeves

Sweatshirts

- for women and men

- seven colour variants to choose from

- numerous printing areas possible (e.g. front chest area, sleeves or neck area)

Bags

- short or long handles possible

- large colour selection

- perfect as a promotional gift

7. Why choose screen printing?

With screen printing, printing is done directly onto the fabric, and not just on a backing material, so that a high level of wearing comfort is guaranteed even with large printed designs. Colour gradations or gradients can also be generated by rasterisation. So you are completely free in your choice of designs!

When printing on dark or vibrantly coloured textiles, optimum colour results are achieved because we use discharge printing for this purpose. The area to be printed is discoloured and simultaneously printed so that the colour brilliance and opacity can be increased. Up to 14 colours can be used for screen printing – no matter whether you want to print designs with many details or large-area prints on coarse fabrics. The use of screen printing for textiles pays off, especially if you seek durability.